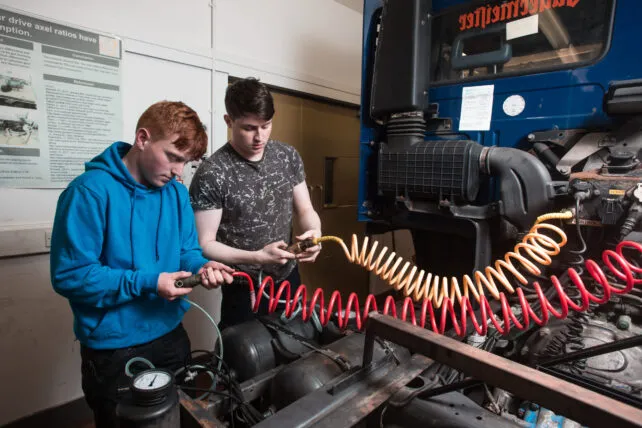

What are the entry requirements?

Leaving Certificate

A minimum of 2 H5 & 4 O6/H7 grades in six Leaving Certificate subjects, including Mathematics and English or Irish.

Mature Applicants

Candidates applying as mature applicants may be required to attend an interview and may be requested to take an aptitude test to prove their suitability for a place on this programme.

Level 6 Craft Certificate (Trade) such as Fitting or Toolmaking, or National/Higher Certificate

Candidates who hold a Senior Trade Certificate and/or National Craft Certificate or holders of a National/Higher Certificate (Level 6) in Engineering or Technology may be considered for admission to Year 2 of this programme subject to a satisfactory interview.

International Applicants

International applicants should apply directly to the International Office at TUS, allowing plenty of time for completing the visa process. Applications for September start should be made by 1st June at the latest to ensure visas are processed in time. You should familiarise yourself with visa processing times for your country of origin to ensure you make a timely application. Find out more here.