Circular Bovine and Ovine Co-Products Valorisation

Project Reference Number This project has received funding from Department Agriculture Food and the Marine (DAFM) 2023 Policy & Strategic Studies Research Call under grant agreement Reference: 2023RP1040.

Duration 48 months (1st December 2023 – November 30th 2027)

Summary

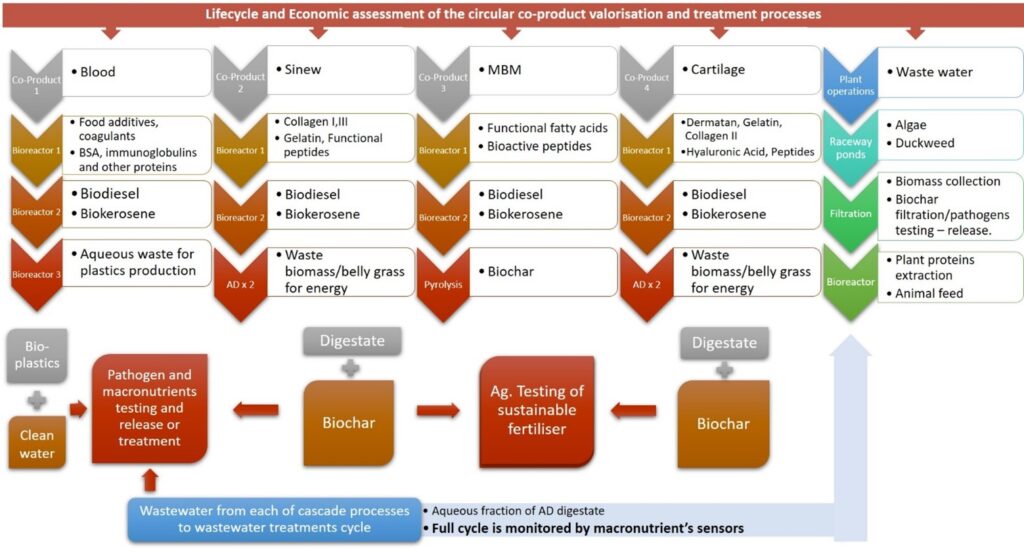

Designed for the Meat Industry, one of the key indigenous sectors in Ireland, the project is valorising the lowest value co-products from cattle and sheep such as cartilage, hides, meat and bone meal (MBM), and blood that are often being incinerated and associated with the high treatment cost. The project’s overall objective is to create at least three bespoke biorefinery processes for the valorisation of bovine and ovine co-products, and upscale enzymatic hydrolysis of meat by-products and their cascade of downstream processing from laboratory size to at least 1000L with the production of raw materials for cosmetics or nutritional supplements. To complete the circular process, factory-generated wastewater from abattoirs will be treated to produce clean water by supporting the growth of algae and duckweed with the potential for the production of fertilisers, bioenergy and bioplastics. The creation of a circular bio-economy model for meat technology with positive economic, environmental, and social impacts will be required to enable the industry to address sustainability challenges.

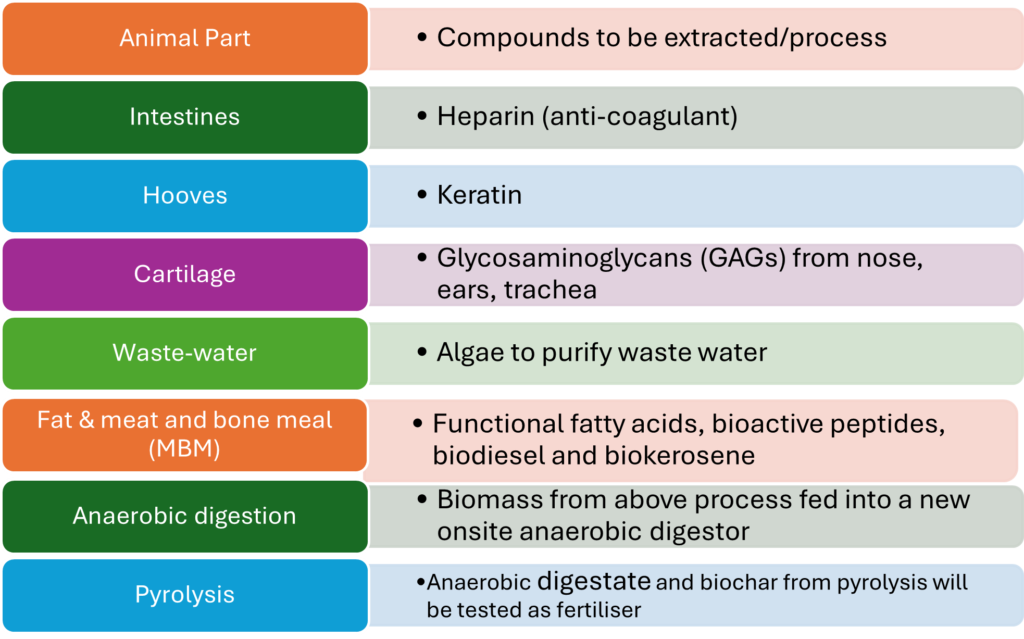

Figure 1. Overview of CirCoVa

Aims & Objectives

To reach this, the following specific objectives have been defined:

- Adopt and upscale co-products preparation protocols to at least 1000L volumes.

- Adopt and upscale enzymatic fermentation to at least a 1000L reactor.

- Adopt and upscale of downstream of multi-stage enzymatic digestion processes.

- Valorise and purify factory wastewater.

- Optimise and upscale waste-to-energy processes.

- To test resulting value-added products for their purpose suitability.

- To test for, and remove, potential impurities and pathogens from produced nutraceuticals, fertilisers and water.

- Combine the upscaled processes into a circular system, ready for deployment.

- Produce economic, social and life-cycle assessments of the circular processes for speedy implementation.

- To demonstrate to the industry partners a fully assessed circular bioprocesses, ready for implementation in their production and a complete path to new processes development, for them to undertake in future.

Figure 2. Overview and summary of CirCoVal objectives

TUS Activities

TUS will valorise various animal parts which are currently considered waste from sheep and cattle focusing on the following:

Contact Details

Project Co-ordinator:

Dr Lena Madden

Senor Business Development Scientist, Shannon Applied Biotechnology Centre

Technological University of the Shannon, Moylish Park

Limerick, Ireland, V94 EC5T

Email: Lena.Madden@tus.ie

Principal Investigator:

Dr Patrick Murray,

Head of Research

Technological University of the Shannon, Moylish Park

Limerick, Ireland, V94 EC5T

Email: Patrick.Murray@tus.ie

Partners

This project is led by Technological University of The Shannon with participation from the following partners: Teagasc Ashtown, University College Dublin, University College Cork, Dawn Meats, Kepak, Ashbourne Meats Processing, Irish Bioeconomy Foundation, Arigna Fuels, Loop Head Together, Liffey Meats, MyGug and BioConnect Innovation Centre.