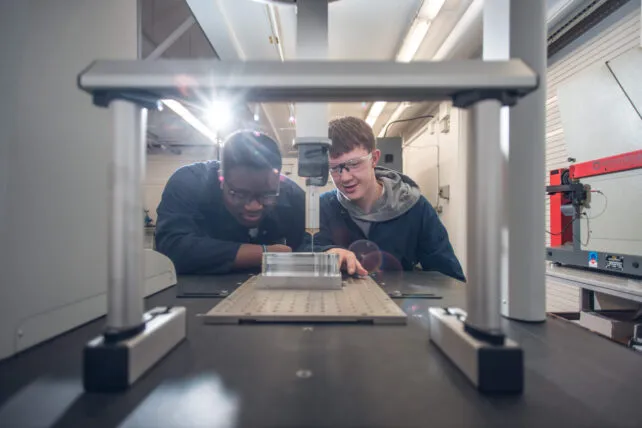

This module involves an in-depth study of automated manufacturing systems for a precision engineering environment. Advanced technologies that integrate precision engineering processes are examined by the learner who already has an in-depth knowledge of the precision engineering processes. The automation for part realisation from the process initialisation to the final stages of production can greatly enhance efficiencies and these are studied in great detail. The manufacturing systems and processes that can be automated are examined.

This module is semesterised. Students will be assessed on their learning by a variety of strategies including continuous assessment, course work and examinations. Continuous assessment is worth 50% and the final exam is worth 50%.

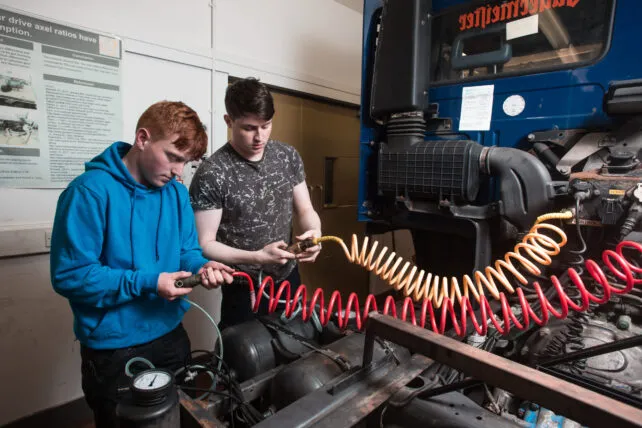

All elements of the module are predicated upon safety and ethical considerations as required by a code of good practice.